Ensuring Safe and Efficient Natural Gas Production with Zeochem

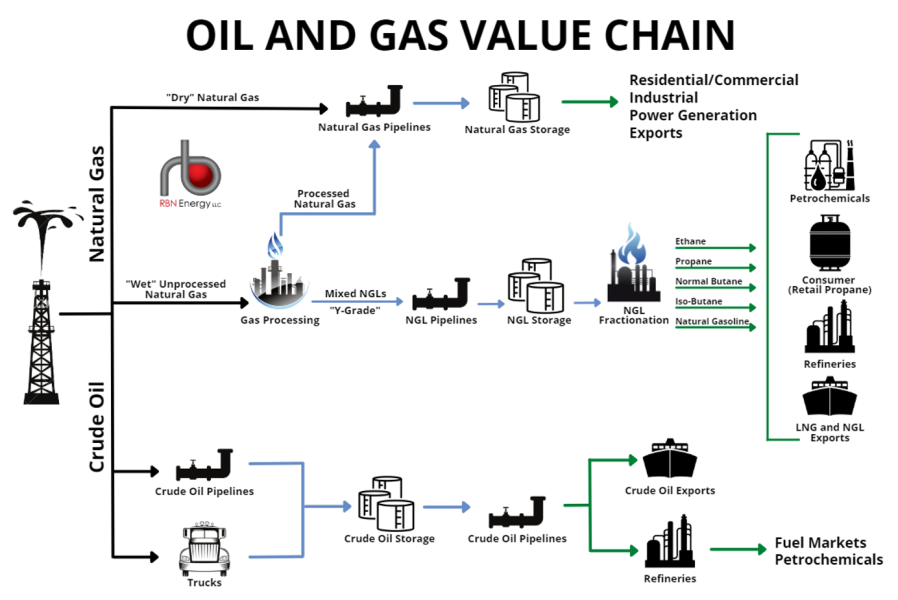

When natural gas is extracted from the ground, it is rarely ready for immediate use. It must first undergo critical processing to meet stringent safety, performance, and environmental standards before it can be delivered to consumers. Managing the water content and other impurities in the gas stream is essential to ensure it is safe to burn and efficient for applications ranging from power generation to residential and industrial use.

Zeochem is a premier global manufacturer of molecular sieve products, with deep roots in Switzerland and a reputation for excellence. We understand the complexities involved in natural gas dehydration and proudly offer high-quality solutions tailored to your specific needs. Our products and technical expertise support the natural gas industry in achieving safe, efficient, and environmentally responsible operations.

To meet these exacting standards, Zeochem’s molecular sieve adsorbents are the preferred choice for gas dehydration. These adsorbents are made of crystalline aluminosilicates, also known as zeolites. Thanks to their unique structure, zeolites can adsorb water molecules at extremely low concentrations. With a high surface area and strong ionic forces, they are exceptionally effective at removing water and other polar contaminants from natural gas.

At Zeochem, we are committed not only to delivering high-quality products but also to providing comprehensive technical support. Our team of experts is always ready to offer personalized guidance, whether you need assistance selecting the right product, optimizing your system, or troubleshooting specific challenges. Trust Zeochem to be your partner in navigating every step of the natural gas dehydration process.

ZEOCHEM ALOX F activated alumina has high crush strength and very low abrasion. ALOX F allows for minimum polymerization of unsaturated hydrocarbons below 65°C.

ZEOCHEM ALOX F activated alumina is used in the drying of gases (such as Air, CO2, SF6, NH3, CO, H2S, and Cl2) and liquids (such as gasoline and chlorinated, fluorinated, or aromatic hydrocarbons) where high thermal and mechanical resistance is required.

ZEOCHEM ALOX F is also used as a guard layer at the inlet of many vapor phase molecular sieve beds. The activated alumina product has high capacity for any liquids that may be present in the feed to the unit. In this service, ALOX F helps protect the molecular sieve bed from damage as a result of heavy hydrocarbon and moisture condensation and liquids carryover from upstream process units.

ZEOCHEM® Z3-01 It is the potassium form of the A-type molecular sieve structure and has an effective pore opening of 3 Ångstroms (0.32 nm).

ZEOCHEM® Z3-01 is a general purpose grade of 3A molecular sieve often used in dehydration of liquid streams or as a general purpose desiccant. It has high hydrothermal stability, which makes it optimal for regenerative applications.

ZEOCHEM® Z3-01 has a controlled pore structure, which allows for exclusion of compounds commonly adsorbed on molecular sieves with larger pore sizes while still allowing for adsorption of water. This makes it an effective product for dehydration of gases and liquids containing high levels of sulphurs, oxygenates, etc. It is also widely used in the dehydration of refrigerants.

ZEOCHEM® Z3-01 will adsorb molecules with kinetic diameter of less than 3 Ångstroms and will exclude larger molecules.

ZEOCHEM® Z3-06 It is the potassium form of the A-type molecular sieve structure and has an effective pore opening of 3 Ångstroms (0.32 nm).

ZEOCHEM® Z3-06 has excellent physical properties and a controlled pore structure, which gives it particularly high hydrothermal stability when used in regenerative applications such as natural gas dehydration. It is widely used in applications where co-adsorption of sulfur compounds and carbon dioxide must be minimized. The narrow pore size also minimizes co-adsorption of hydrocarbons and shows energy savings over other products.

ZEOCHEM® Z3-06 is optimized for the drying of gas and liquid streams where the formation of carbonyl sulfide must be reduced in the presence of CO2 and H2S.

ZEOCHEM® Z3-06 will adsorb molecules with kinetic diameter of less than 3 Ångstroms and will exclude larger molecules.

ZEOCHEM Z3-03 It is the potassium form of the “A” type structure and has an effective pore opening of 3 Ångstroms (0.32 nm).

ZEOCHEM Z3-03 combines the controlled pore structure and hydrothermal stability of 3A products with properties to maximize selectivity for moisture in polar gas or liquid streams, to ensure strong dynamic performance in pressure swing drying applications, and to provide good physical properties such as high attrition resistance and crush strength.

ZEOCHEM Z3-03 was developed and formulated for the drying of alcohols and other polar gases or liquids, most notably for vacuum pressure swing adsorption (VPSA) technology.

ZEOCHEM® Z4-01 It is the sodium form of the A-type molecular sieve structure and has an effective pore opening of 4 Ångstroms (0.38 nm).

ZEOCHEM® Z4-01 is the standard grade, while other grades have been developed with properties optimised for particular applications. It is used in general dehydration applications and in synthesis gas treating. It has optimum hydrothermal stability, which makes it preferable in some regenerative applications.

ZEOCHEM® Z4-01 is commonly used in various gas and liquid treating applications such as dehydration of hydrogen, carbon dioxide, air, and inert gases; synthesis gas treating for removal of water, carbon dioxide, ammonia, methanol, etc; and dehydration of non-polar liquids. It is also used as a packaging desiccant.

ZEOCHEM® Z4-01 will adsorb molecules with kinetic diameter of less than 4 Ångstroms and will exclude larger molecules.

ZEOCHEM® Z4-04 It is the sodium form of the A type molecular sieve structure and has an effective pore opening of 4 Ångstroms (0.38 nm).

ZEOCHEM® Z4-04 was specially developed for optimum performance in the dehydration of natural gas and other hydrocarbon streams.

ZEOCHEM® Z4-04 has excellent physical properties and a controlled pore structure, which gives it particularly high hydrothermal stability when used in regenerative applications such as natural gas dehydration. It is widely used in applications where co-adsorption of sulfur compounds and carbon dioxide is not an issue.

ZEOCHEM® Z4-04 will adsorb molecules with a kinetic diameter of

less than 4 Ångstroms and will exclude larger molecules.

ZEOCHEM Z5-01 It is the calcium form of the A-type molecular sieve structure and has an effective pore opening of 5 Ångstroms (0.48 nm).

ZEOCHEM Z5-01 has excellent physical properties and a controlled pore structure, which gives it particularly high hydrothermal stability when used in regenerative applications such as natural gas dehydration. It is widely used in applications where hydrogen sulfide or carbon dioxide must be removed from the feed stream.

ZEOCHEM Z5-01 is commonly used in treating natural gas and other hydrocarbon streams for removal of H2O, CO2, H2S, CO, N2, and mercaptans. It is also used for the separation of straight-chain paraffins from streams containing branched and cyclic hydrocarbons. Additionally, it is used for the production of high purity nitrogen, oxygen, hydrogen, and inert gases from air and other gas streams and is especially suitable for pressure swing adsorbers.

ZEOCHEM Z5-01 will adsorb molecules with kinetic diameter of less than 5 Ångstroms and will exclude larger molecules.

ZEOCHEM Z5-05 has excellent physical properties and a controlled pore structure, giving it excellent equilibrium and dynamic performance along with optimum physical strength and high hydrothermal stability. It is ideally suited for dehydration and the removal of small sulfur compounds including H2S, methyl-mercaptans, and ethyl- mercaptans. Z5-05 also has good capacity for removing small concentrations of CO, CO2, and oxygenates, such as methanol and ethanol.

ZEOCHEM Z5-05 is recommended for use in various PSA processes for removal of H2O, CO, CO2, and other polar compounds. For new units Z5-05 can be used to reduce the required vessel size compared to generic 5A materials, while use of Z5-05 in existing units will offer enhanced adsorption performance with the same bed volume.

ZEOCHEM Z5-05 will adsorb molecules with a kinetic diameter of less than 5 Ångstroms and will exclude larger molecules.

ZEOCHEM Z10-01 It is the sodium form of the X-type molecular sieve structure and has an effective pore opening of 9 Ångstroms (0.9 nm).

ZEOCHEM Z10-01 has an open pore structure, giving it excellent equilibrium and dynamic performance, as well as high physical strength and hydrothermal stability. It is well suited for treating in liquid phase or gas phase for concurrent adsorption of one or more compounds.

ZEOCHEM Z10-01 is often used for removal of polar compounds, such as H2O, CO2, sulfur, and certain organic compounds, from less polar fluid streams, such as in synthesis gas treating applications.

ZEOCHEM Z10-01 will adsorb molecules with a kinetic diameter of less than 9 Ångstroms and will exclude larger molecules.

ZEOCHEM® Z10-02 It is the sodium form of the “X” type molecular sieve structure and has an effective pore opening of 9 Angstrom (0.9 nm)

ZEOCHEM® Z10-02 is developed and designed for the removal of carbon dioxide from air, typically in cryogenic air pre-purification units and in syn gas units using a TSA process.

ZEOCHEM® Z10-02 has a high carbon dioxide capacity while maintaining the integrity of the beads. This, together with excellent dynamic characteristics allows a maximum physical usage of the available adsorber bed volume in existing plants.

ZEOCHEM Z10-04 It is the sodium form of the “X” type molecular sieve structure and has an effective pore opening of 9 Angstroms (0.9 nm).

ZEOCHEM Z10-04 is developed and designed for the production of oxygen rich gas streams from air. It is used in larger scale units. It has a high selectivity for nitrogen using PSA technology.

ZEOCHEM Z10-04 combines a very open pore structure giving excellent equilibrium and dynamic performance, together with optimum physical strength and high selectivity for nitrogen. The excellent dynamic characteristic allows a maximum usage of the available adsorber bed volume.